The Sleeping Giant Awakes: American Assembly Lines During WWII

Throughout the Second World War, countries ramped up their production efforts to levels not previously seen. The one that stood out the most with regard to these efforts was the United States. While the nation joined the war late, it quickly ramped up efforts in all sectors, allowing for the production of two-thirds of the military equipment used by the Allied forces. The following images show just how busy America’s assembly lines were during WWII.

WWII saw the ramping up of assembly lines

When the Second World War began, the US had no intentions of getting involved, as the public didn’t think it was their war to fight. Coming out of the Great Depression, the country’s industry were nothing impressive, nor was its military. The US Army, now regarded as one of the best in the world, was only 17th in terms of size and power in 1939.

Dorothy Miller and Sylvia Dreiser working an eight-hour shift at a Buick plant during the Second World War. (Photo Credit: Ann Rosener / Library of Congress / Wikimedia Commons / Public Domain)

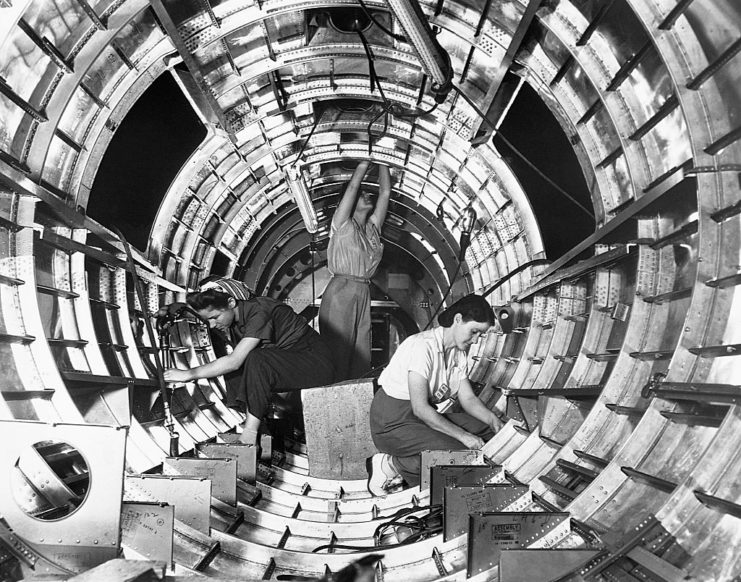

Fuselage and wing components for the Consolidated B-24 Liberator being assembled at the Ford Motor Company Willow Run Bomber Plant, December 1942. (Photo Credit: Keystone / Hulton Archive / Getty Images)

Following the Japanese attack on Pearl Harbor, the US officially entered the war. President Franklin D. Roosevelt knew serious changes had to be made to the country’s industrial channels to ensure the military was well-stocked.

He set some ambitious goals for American factories. In 1942, he asked them to produce 60,000 aircraft, while the following year’s request was over double that, at 125,000. During this time, plants were also tasked with manufacturing 120,000 tanks and 55,000 anti-aircraft guns.

Workers assembling M3 Stuarts, 1942. (Photo Credit: Hulton Archive / Getty Images)

To accomplish the demand placed upon them by the US entering WWII, assembly lines had to make a number of changes. Prior to the attack on Pearl Harbor, the nation’s unemployment was at 14.9 percent. As the majority of the men who still held factory jobs went off to fight, there was a need to replace them, if only temporarily.

This wound up having a positive effect on unemployment statistics, with the percentage of unemployed Americans dropping down to 1.9 percent by 1945. The individuals who replaced those who had been deployed were primarily women and people of color, along with those who were deemed unfit to serve, either due to physical ailments or other reasons.

Constructing vessels for naval warfare

Although not explicitly mentioned in Roosevelt’s goals, assembly lines also increased the production of naval vessels throughout WWII. In fact, factories were producing ships so quickly that, by 1943, the number being launched had surpassed the amount of Allied ships that had been sunk since the beginning of the conflict.

Shipbuilders constructing cowls for American vessels, 1942. (Photo Credit: Hulton-Deutsch Collection / CORBIS / Getty Images)

Martha Bryant and Eulalie Hampden operating a bolt-cutting machine at Todd Shipyards, 1943. (Photo Credit: Alfred T. Palmer / Library of Congress / Wikimedia Commons / Public Domain)

A variety of vessels were produced during this time. One of the earliest production efforts implemented was 1940’s Emergency Shipbuilding Program, which was enacted to quickly construct cargo ships that would carry American materials and troops overseas.

By September 1945, the program had churned out nearly 6,000 vessels. While cargo ships were primarily constructed, the program was expanded to include tankers, frigates and attack vessels as the war progressed.

Workers constructing assault boats for the US Marine Corps, 1941. (Photo Credit: U.S. National Archives and Records Administration / Wikimedia Commons / Public Domain)

Josie Lucille Owens constructing the SS George Washington Carver at Kaiser shipyards, 1943. (Photo Credit: E.F. Joseph / Anthony Potter Collection / Getty Images)

Higgins Industries also produced many of the landing craft used on D-Day, which were among the most important parts of America’s naval production during the Second World War. In fact, they were so instrumental to the war effort that Gen. Dwight Eisenhower went so far as to say, “If Higgins had not designed and built those LCVPs, we never could have landed over an open beach. The whole strategy of the war would have been different.”

Assembly lines produced a number of aircraft during WWII

The efforts made in the aircraft manufacturing sector were impressive to say the least. Over the span of five years, it went from being the 41st most productive industry in the country to the first. To put this into perspective: in 1939, only 3,000 aircraft left the assembly line, while by the end of WWII, some 300,000 had been built for the war effort.

Unlike many of the other American industries, aircraft production ramped up before the country had even joined the war.

Workers polishing the nose cones of aircraft, 1943. (Photo Credit: FPG / Hulton Archive / Getty Images)

Although a neutral county in the early years of the war, the US was incentivized to increase production following a demand from the United Kingdom and France. Both countries were producing their own aircraft, but wanted the American supply to bolster their fleets.

As this arrangement didn’t violate the nation’s neutrality, government officials agreed. The 1939 Neutrality Act allowed other countries to purchase armaments from them so long as they paid in cash and transported their purchases without American assistance.

Workers assembling the tail fuselage of a Boeing B-17F Flying Fortress during World War II. (Photo Credit: CORBIS / Getty Images)

The Corsair factory in Stratford, Connecticut during World War II. (Photo Credit: Bettmann / Getty Images)

When the US officially went to war, many companies switched production to aircraft. Notable automobile manufactures, such as General Motors, Chrysler and Rolls-Royce, began manufacturing different aircraft parts.

Manufacturing weapons of war

There were many different weapons created as part of the American production effort during WWII, including a variety of guns and artillery. Along with shifting manufacturing to aircraft components, the automobile industry also became heavily involved in the making of anti-aircraft guns.

Bofors 40 mm anti-aircraft guns being assembled at the Firestone Tire and Rubber Co. Plant, 1942. (Photo Credit: Bettmann / Getty Images)

Ruby Barnett testing a .50-caliber anti-aircraft gun, 1942. (Photo Credit: Bettmann / Getty Images)

As with many factories, the Mattatuck Manufacturing Company, the American Brass Company, and the Chase Brass and Copper Company also transitioned into making weapons. Mattatuck produced cartridge clips for the Springfield rifle, while Chase Brass made a staggering 50 million mortar shells and cartridge cases, as well as a billion smaller bullets.

The US spent the most money on munitions production than any other country during the war. Between 1939-44, roughly $106.3 billion worth were produced, making up half of the Allies’ entire expenditures.

Worker with artillery shells, 1940s. (Photo Credit: Hulton Archive / Getty Images)

Workers assembling 40 mm anti-aircraft guns, 1940s. (Photo Credit: Hulton Archive / Getty Images)

Overall, the country’s dedication to the wartime industry was impressive. While numbers vary as to just how many ships, tanks, weapons and aircraft American factories produced during the conflict, the effort undertaken by industries and civilians alike was key to making the assembly line the powerhouse it was.